Selected customer:

Case Studies

Powering the Construction of a Nuclear Processing Facility

With an estimated value of $6.5 billion, the (UPF) is the US Department of Energy’s biggest investment in Tennessee since World War 2. Located in Oak Ridge, the design consists of a multi-building, state of the art complex that will support the nation’s nuclear weapons stockpile and provide fuel for various U.S. Navy vehicles.

Using Power Transformation Units on Large Construction Projects

One of North America’s largest construction and engineering organizations has trusted Ericson products on a variety of job sites.

Illuminating a Nuclear Boiling Water Reactor During Maintenance Procedures

Nuclear generating stations are consistently evaluating the safety of their grounds and equipment.

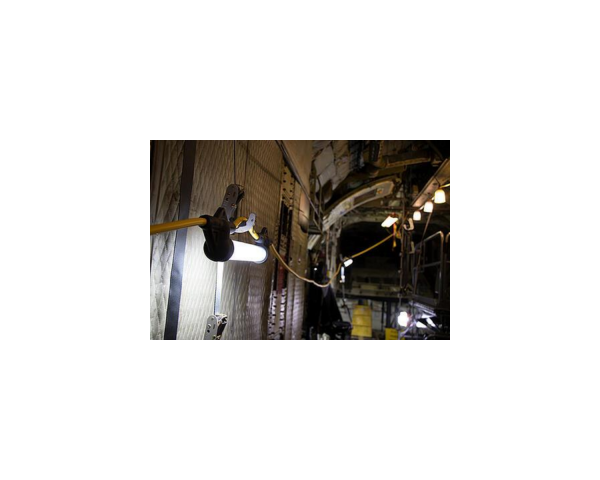

Streamlining the Maintenance of the C-130 Hercules Aircraft

Originally designed over 65 years ago, Lockheed’s C-130 Hercules has the longest continuous military aircraft production run in history.

Illuminating the US Navy

Founded in October 1775, the US NAVY is the largest navy in the world.